-

Company:

UMCC is a designer and manufacturer of high

performance RF/Microwave components and subsystems.

Since its founding

almost two decades ago, the company has established and followed a

tradition of excellence supplying reliable high quality products

into a wide range of industries such as wireless and satellite

communications, medical science, surveillance, security, industrial

automation, military/defense sector products, space exploration,

aviation, biometrics, broadcasting, and similar. UMCC is a privately

owned company located in Northern Virginia USA.

-

Technical

/ Design Capabilities:

UMCC is a

technically-oriented company with specialized engineering

capabilities in RF/Microwave hardware design and development. Our

team of engineers and technicians have years of hands-on experience

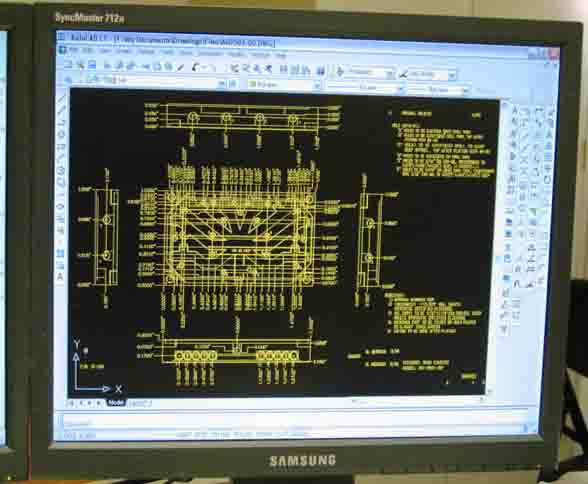

in product development. Computer aided design tools are widely

applied in different stages of product-design, development, and

manufacturing.

Product design starts with an engineering concept to meet a specific

product specification. RF/Microwave circuitry is designed along with

preliminary engineering calculations. Electrical circuitry and

layout is modeled on a computer simulator. The computer model

includes real-world physical parameters where tolerances, parts

limitations, and manufacturing yields are accounted for. Touchstone

simulator is among the software tools frequently used for analysis

and optimization of such circuits by our engineers. After each

circuit model is fully optimized, a circuit layout is generated

along with a mechanical package to house the circuit elements such

as connectors, feeds, substrate/PCB, and other parts. Mechanical

package design is done with AutoCAD software. Ultimately, a

preliminary test prototype is developed and tested. Upon success of

the prototype a complete set of documentation is generated. The

documentation package includes parts lists, schematics, assembly

drawings, CNC machining programs, manufacturing instructions,

testing/tuning procedures, test data sheets, outline drawings,

marking instructions, etc.

-

Marketing

/ Customer Service:

UMCC marketing is supported directly by engineers with a complete

understanding of our products, associated applications, and design

limitations. Our engineers are ready to discuss any technical

matter relating to products supported by UMCC. Once technical

parameters are discussed and agreed upon, quotations are submitted

to the customer for consideration. UMCC is also represented by

technical sales representatives covering different territories and

many countries around the globe. To find the UMCC representative

closest to you, please visit our web site for current listings of

UMCC distributors and representatives.

-

Production

/ Process Control:

Hardware

production takes place under complete quality and process control.

Each production step from preparing the bill of materials to

assembly, testing, screening, and shipping is constantly monitored

to assure the consistency, quality, and performance of the products

manufactured. Individual units are serialized and fully tested for

performance prior to shipment to the customer. Test data and

certificates of compliance are provided to the customer at no

additional cost. Standard UMCC products are built to the best

commercial grade. UMCC guarantees its products to meet and exceed

many environmental extremes such as high/low temperature, altitude,

vibration, and others. All products offered by UMCC are subjected

to routine steps in screening such as temperature shock cycles and

3-axis vibration testing to assure product reliability.

-

Warranty /

Product Support:

UMCC

warrants its products to be free from defects in material and

workmanship. The standard warranty is one year from date of

shipment. Any component found to be defective will be repaired or

replaced free of charge during this warranty period. Technical

support is available from UMCC engineers and product specialists for

the entire life span of each and every product. UMCC also maintains

an archive of final test data taken on each unit shipped to the

customer.

-

Here is

a summery of UMCC's capabilities:

In house product design

& development

In house product design

& development

Fast custom built

prototype development

Fast custom built

prototype development

In house mechanical

design and machining

In house mechanical

design and machining

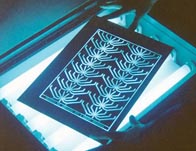

In house PCB and

microwave circuit etching

In house PCB and

microwave circuit etching

Complete in house

assembly and integration

Complete in house

assembly and integration

In house RF/Microwave

testing and tuning

In house RF/Microwave

testing and tuning

-

|

|

|